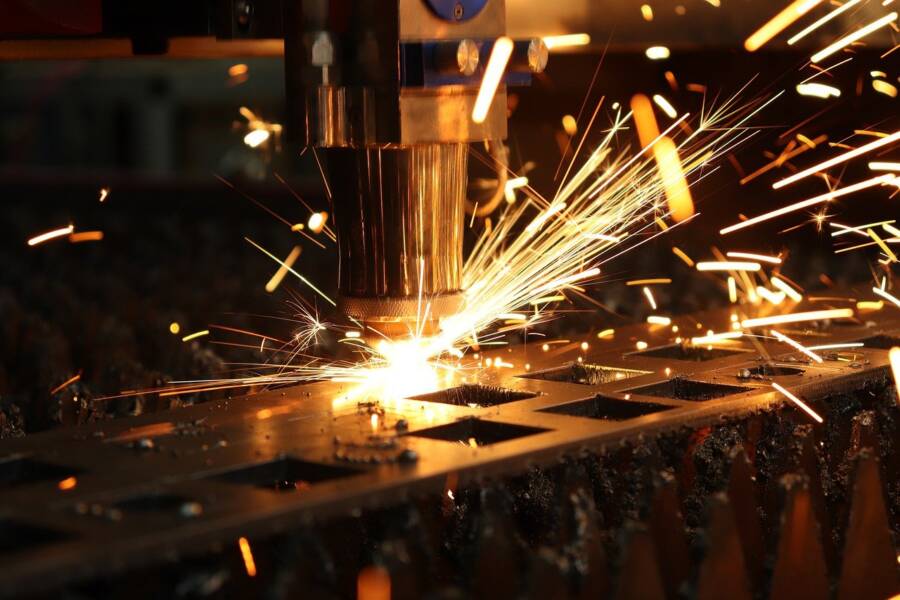

The manufacturing industry is one that is constantly changing and evolving. In order to stay ahead of the competition, it is important to use the latest technology and equipment. CNC machining is one such technology that can help businesses in the manufacturing industry to stay competitive.

What is CNC?

CNC stands for Computer Numerical Control and means that a computer is responsible for a lot of the machines tasking that can be activated with just the click of a few buttons. This allows businesses to create precision parts and components quickly and efficiently. CNC machining can be used for a variety of applications, including milling, turning, drilling, and cutting.

Why use CNC machining?

CNC machining can help businesses in the manufacturing industry to stay competitive by increasing accuracy, decreasing manufacturing time, lessening space required for production, and increasing profitability. Additionally, CNC machining allows businesses to produce higher quality goods that are safe for consumers while reducing environmental impact.

There are many benefits of using CNC machines like CNC lathe in the manufacturing industry. Some of these benefits in more detail include:

1) Increased accuracy –

CNC machining allows businesses to produce products that are more precise. This allows manufacturers to lessen the likelihood of faults, defects, and errors.

2) Decreased manufacturing time –

CNC machining helps to decrease manufacturing times. With all tasks being completed by the computer system, it dramatically decreases set-up times and increases productivity.

3) Lessens space required for production –

A common problem found in some parts of the world is that there is not enough space available for businesses wishing to produce goods on a larger scale. CNC machining allows businesses to reduce the amount of floor space they use while still producing large amounts of components quickly and efficiently

4) Increases profitability –

When new technology is introduced into any industry, new opportunities arise for businesses within that sector which can increase overall profitability.

5) A wide variety of tough materials can be worked on –

CNC machining is not limited to only certain types of material, which allows companies to use a wider range of materials during production. This increases the number of products that they are able to create and sell.

6) Higher quality –

CNC machining allows manufacturers to have more control over the production process because of accurate components being produced on schedule. This helps businesses to produce higher quality goods that are safe for consumers.

7) Lessens environmental impact –

With new technology being introduced into the manufacturing industry, it has allowed businesses who are using new equipment such as CNC machines, to decrease their carbon footprint. By producing higher quality parts with less waste, this reduces pollution and helps to improve the environment.

In Summary

Overall, there are many benefits of using CNC machining in the manufacturing industry. It helps businesses to be more accurate, efficient, and profitable. Additionally, it helps to reduce environmental impact and allows companies to use a wider range of materials. With all these benefits, it is easy to see why CNC machining is quickly becoming a popular choice for businesses in the manufacturing industry.

Ingrid Maldine is a business writer, editor and management consultant with extensive experience writing and consulting for both start-ups and long established companies. She has ten years management and leadership experience gained at BSkyB in London and Viva Travel Guides in Quito, Ecuador, giving her a depth of insight into innovation in international business. With an MBA from the University of Hull and many years of experience running her own business consultancy, Ingrid’s background allows her to connect with a diverse range of clients, including cutting edge technology and web-based start-ups but also multinationals in need of assistance. Ingrid has played a defining role in shaping organizational strategy for a wide range of different organizations, including for-profit, NGOs and charities. Ingrid has also served on the Board of Directors for the South American Explorers Club in Quito, Ecuador.