Hydraulic systems have replaced other alternatives across multiple avenues with greater efficiency and cost to value ratio. The systems are so popularized now that they are built into our everyday life. Here you can read more about heating repair service.

Hydraulics systems have been ingrained into transport, entertainment and regular service provision alongside a variety of other day-to-day avenues. Below are a few ways you might experience these systems without even knowing it.

Amusement Park rides

Most rides in amusement parks use pneumatic or hydraulic systems. Hydraulics boost the ability of these rides to move through quick turns and twists while keeping the cars on track.

Elevators

While some elevators use string pulls, a large selection opts for hydraulic presses. These hydraulic elevators operate with a pump that pushes liquid through a cylinder valve which causes pressured movement of the elevator unit. Hydraulic elevators are cheaper and more efficient than other alternatives in the market.

Automated door closers

Hydraulics can be facilitated into different items, with their use in door closers pointing to the versatility. Hydraulic closers are attached to the door and frame, with released pressure slowly shutting the door automatically without slamming it.

Airplanes

Airplanes feature hydraulics in their brake system. They wheel and brake pedal are connected with hydraulic fluid which helps to control speed during landing. Planes use hydraulics in the wing flaps and flight controls as well.

Car brakes

Like aero planes, cars also feature hydraulics in their brakes. By compressing the brake pedal, a driver will set off the hydraulic process that begins to slow down the car. The hydraulic brake system replaced cable connected alternative and has proven a safer way to stop your car.

Shock absorbers

Shock absorbers in different types of vehicles rely on hydraulics. The aggressive motion over bumps or into potholes releases hydraulic fluid that balances out the pressure while ensuring uninterrupted comfort levels for the users.

Tips to increase the longevity of hydraulic components

Like other items, hydraulic systems will break down as a result of wear and tear. You need to optimize your usage and maintenance to prevent serious and costly damage to any hydraulic components for continued efficiency in their use. That said, there are plenty of industrial surplus equipment that could help you restore your hydraulic components to their desired state. If you have trouble accessing or setting these up, you could consider professional help to ensure you restore your hydraulics to optimal function with minimal risk.

Here are a few tips to help you ensure increased longevity for hydraulics around you.

Hydraulic pumps

Always listen in for unusual sounds coming out of the unit’s housing. If the pump drive and mount experience vibration more than expected, your pump may require urgent action. Always inspect your pump for high heat signs and excessive temperature changes as these can increase the rate of wearing out.

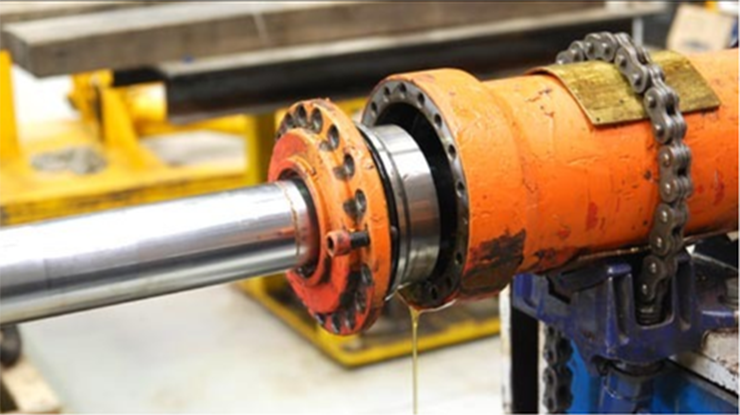

Hydraulic cylinders

Moisture-induced rust can cause corrosion in the cylinder sleeves, which may in turn compromise the efficiency of your cylinder. To avoid this, you could consider storing your machines with retracted cylinders whenever possible. You should also regularly check out your cylinders for any side loading and wear that may arise from excessive overuse.

Hydraulic hoses

You need to explore the entire length of your flexible hose for any kinks and routing that may compromise hydraulic authenticity. You should replace any damaged hoses immediately, especially any frayed options. You should always use recommended size hoses for specific machines.

Hydraulic lines

Always check your metal tubing lines for any fillings. You should also tighten any loose fillings during replacement or repair. Finally, always make sure your seals have no signs of wear as this can affect the efficiency of your hydraulics.

Hydraulic fluid

You should only buy high quality hydraulic fluid, preferably one which is designed for your specific use. Avoid reusing any fluid wherever possible, with any oil containing unusual components eliminated immediately. You should also invest in hydraulic fluid analysis to protect your system from any unexpected glitches.

Hydraulic filters

You should only purchase recommended filters intended for your specific use. Avoid using any inferior products since these will compromise your entire operation’s efficiency. Lastly, avoid changing your hydraulic oil while still using old filters for improved efficiency.

TechnologyHQ is a platform about business insights, tech, 4IR, digital transformation, AI, Blockchain, Cybersecurity, and social media for businesses.

We manage social media groups with more than 200,000 members with almost 100% engagement.